39 rub test for labels

Ink Rub Tester RT-01 - Labthink Testing Equipment Overview. RT-01 Rub Tester is professionally designed for the abrasion resistance test of surface coating layers of printed materials, e.g. ink layer or photosensitive (PS) coating. This instrument could effectively analyze the problems of poor abrasion resistance, ink layer falling off and poor hardness of coating layers of printed materials. Ink Rub Tester (Sutherland Type / Linear Rub) - PackTest Also known as the Sutherland Rub Tester, this is an equipment to test printed substrates such as plastic films / foils / labels / papers or paper boards for resistance to scuffing / rubbing / smudging when 2 samples are rubbed against each other in a linear motion, under a defined pressure, at a defined speed for a defined number of rubs.

How To Do A Label Marking Durability Test [Video and Infographic ... How to Do an Isopropyl Alcohol Rub Test What you'll need: Isopropyl Alcohol Toothbrush Timer Immerse your label in isopropyl alcohol for 3 minutes. Remove the label from the alcohol. Then, use a toothbrush to scrub the impression 10 times. Repeat steps a-b twice more for a total of 3 cycles. Review the label impression for degradation.

Rub test for labels

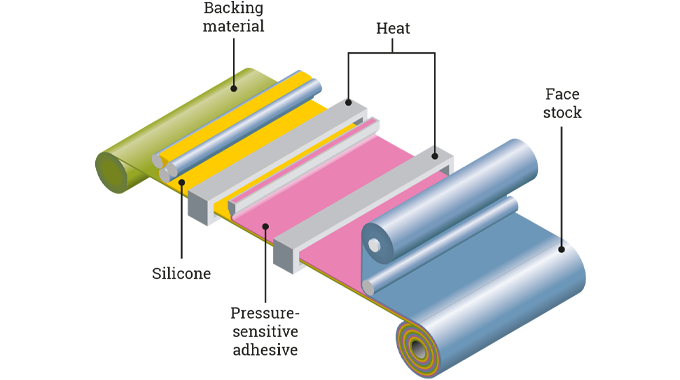

Solvent Resistance Rub Test - ASTM D4752 - TRL This test method is used to determine the degree of cure of a baked film by the paint film resistance to a specified solvent. The Solvent Rub Test is usually performed using methyl ethyl ketone (MEK) as the solvent. The MEK resistance or degree of cure applies to paint topcoats and primers. ASTM D4752 involves rubbing the surface of a baked ... Gardco :: SUTHERLAND Ink Rub Tester Printed Labels & Rub Testing For printed labels, the rub test gauges the amount of abrasion or scuff that may result during shipping, handling or storage. The test may be used for the labels of pharmaceutical products and medical devices, as well as the characters on keypads, for example. These labels must be legible and stand up to wear over time. Test methods for pressure-sensitive labels | Labels & Labeling At the label converter FINAT test methods encompass printing on the label and die-cutting and matrix removal (Figure 8.3). For the label converter key requirements are to test adhesion of the final label and de-lamination properties. ... There are specific rub and scratch resistance tests for UV inks (Figure 8.9). Figure 8.9 Ink adhesion testing.

Rub test for labels. Pharmaceutical Label Testing and Print Qualification - Westpak A Sutherland Rub Test evaluates the scuff or rub resistance of printed or coated surfaces, paper, paperboard, films, and printed materials. In a Chemical Resistance Test, labels can be manually cleaned with IPA and peroxide wipes to determine if the label smudges, smears, or degrades in legibility. Peel Adhesion tests can be used to measure a ... Rub Testing Procedures Explained | Rub Tester | Danilee Co. Mount the strips in the same manner as for a dry rub, using the two-pound test block. Preset the tester for one rub. Place three to six drops of water on the printed surface so that the test block will cover them. Place the block in position and immediately press the "start" button. After one stroke, examine both surfaces for color transfer. Learn Printing Adhesion Testing Like a Pro - InTouch First press the dry white cloth firmly against the printed testing surface and rub back and forth 24 times. For the alcohol rub test, lightly dampen the cloth before similarly rubbing the test surface. Lift the cloth from the testing surface and visually examine it for signs of lifted print from the test surface. Product Quality Control. What is Rub Testing for Print? Rub testing utilizes a specified tool to test the amount of force needed to create damage to the label giving you the information you need to increase the quality of your labels or will give you peace of mind knowing your labels will hold up in shipping and storage environments.

What is the Sutherland Rub Test Procedure? | Danilee Co. To test labels, a rub test machine such as the SUTHERLAND® 2000™ Rub Tester places one label into the machine while a second label is attached to a weight. The labels are then rubbed together at an optimized speed for a predetermined time period, and afterward the shipper or tester can check the labels to assess the abrasion resistance. Scuff tester: best way to test rub resistance of packaging labels The Testronix scuff tester is utilized to test the abrasion resistance of the surface coating layer of printed material in order to analyze the life of the label by simulating the actual application environment. A scuff-resistance test can be used to mimic the abrasion resistance of printed, painted, or polished services. The Sutherland Rub Test: ASTM D5264 | Packaging Compliance Labs ASTM D5264 Standard Practice for Abrasion Resistance of Printed Materials by Sutherland Rub Tester. Packaging Compliance Labs provides ASTM D5264 standard Sutherland Rub testing to gauge the amount of scuffing or abrasion caused during shipping, handling, and storage. For medical packaging this test is critical to ensure that labeling remains ... Sutherland Rub Test | ASTM D5264 | ASTM Abrasion Test | DDL The Sutherland Rub Test is performed by attaching a label to the device while a similar sample label is attached to a weight. The two samples are then rubbed against one another at a controlled speed for a predetermined number of cycles. Once the rubbing stops, the samples are visually inspected to see if the ink has worn off or not.

Ink Rub Tester | Qualitest - WorldofTest.com Best Application: Ink Rub tester on plastic Rub resistance describes the ability of printed material to withstand marking, scuffing or smudge during handling in conversion, packaging, transportation, distribution and use. QT-IRT simulates a similar environment to test the rub resistance on printed materials. Applications Features/Advantages How to Do an Isopropyl Alcohol Rub Test - YouTube UL Compliant Solutions: do you determine the durability of your thermal tran... Ensure Durability Of Labels To Mark Quality Of Products - prestogroup In Ink rub test, a label or printed material is rubbed against an abrasive. It can undergo the rub test 100 times and then may be inspected for readability of the information. This testing is used in any application where it is important to determine that the ink does not fade away. Abrasion resistance is an important property in printed materials. Scratch or Rub Resistance of Labels on Packages - prestogroup ASTM F2497-05 - Standard Practice for Abrasion and Scuff Resistance of Inkjet Media by the Sutherland Rub Tester BS 3110:1959 - Methods for measuring the rub resistance of the print To know more information about its features, price, and technical specifications, give us a call at +91 9210903903 or email us at info@prestogroup.com.

ASTM D 5264 rub testing for labels - DirectIndustry Configurations Standard Configurations Instrument, 8.9N (2lb) Test Block, 17.8N (4lb) Test Block and Rubber Cushion Optional Parts Customized Test Block Please Note: Labthink is always dedicated to the innovation and improvement of product performance and function. Therefore, technical specifications are subject to change without further notice.

Why Is Rub Testing Important? | What is Rub Testing? For printed labels, the rub test gauges the amount of abrasion or scuff that may result during shipping, handling or storage. The test may be used for the labels of pharmaceutical products and medical devices, as well as the characters on keypads, for example. These labels must be legible and stand up to wear over time.

Abrasion, Rub and Scuff Resistance - Smithers The Sutherland Rub Test is performed by attaching a label to the device while a similar sample label is attached to a weight. The two samples are then rubbed against one another at a controlled speed for a predetermined number of cycles. In contrast to the rotary Smithers Rub Tester, the Sutherland Rub Tester employs a reciprocating arc motion.

Rub & Scuff Testing For Your Labels - Advanced Labels NW Your label printer will need a few printed and varnished production labels. The rub and scuff test involves an industry standard two pound or four pound weighted block, with your packaging insert affixed to its base. This weighted insert is then dragged back and forth in an arc across the face of your label at its weakest point.

Testing Labels for Direct Thermal Printing Applications NOTE Using Thermal Transfer labels under Direct Thermal mode (without ribbon) will result in blank labels. To check if you are using the correct labels for the Direct Thermal application, perform a simple scratch test. If the scratch test does not leave any marks, consult your label supplier or use the Thermal Transfer mode (with ribbon).

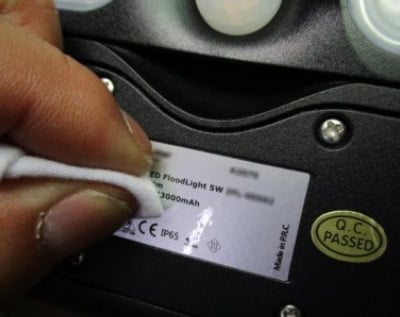

PDF Compliance Guidelines for Marking and Labeling Systems - Ul rubbing label samples with a cloth soaked with one or more liquids, such as water, petroleum spirit (hexane), methylated spirit (ethyl alcohol denatured with methanol), isopropyl alcohol solution or other liquids, and then visually examining the label samples for legibility and adhesion.

Ink Rub Tester - Rub Tester for Printing Inks And Coatings Manufacturer ... Ink Rub Tester is applicable in ink rub test of ink layer of materials like labels, folding cartons, corrugated boxes etc. Ink Rub Tester can help users to analyze the reasons of lower abrasion assistance, ink layer falling-off, lower printable of PS boards and adhesion of coating layers of other products.

Benefits of Ink Rub Testing | Sutherland 2000 | Danilee Co. An ink rub test is a test of a label whereby a label is rubbed against an abrasive. It might be rubbed several hundred times and afterwards the label is inspected for readability of the information on the label. Different fluids can also be employed like such as alcohol and even soaps.

Standard Test Method for Rub Abrasion Mar Resistance of High Gloss Coatings Standard Test Method for Rub Abrasion Mar Resistance of High Gloss Coatings. Version. D6279-20 Active. D6279-15 D6279-03R13 D6279-03R07 ...

Self-adhesive label rubbing resistance test - Xinxing Label Self adhesive label rubbing resistance test Watch on In order to detect the abrasion resistance of the printed label, it is necessary to perform a rub resistance test on the label. Fix the label on the anti-friction testing machine, apply a certain amount of gravity, and use the rubber to rub the label at a fixed speed.

Label Durability Testing - Eurofins Medical Device Testing Choose Eurofins Medical Device Testing to help you: Assess the robustness of your labels to verify that your barcodes will remain readable after being subjected to the stresses of shipment. Ensure your products meet the latest UDI regulations. Testing Available: Tape Testing - ASTM F2252. Sutherland Rub Testing - ASTM D6264.

Test methods for pressure-sensitive labels | Labels & Labeling At the label converter FINAT test methods encompass printing on the label and die-cutting and matrix removal (Figure 8.3). For the label converter key requirements are to test adhesion of the final label and de-lamination properties. ... There are specific rub and scratch resistance tests for UV inks (Figure 8.9). Figure 8.9 Ink adhesion testing.

Gardco :: SUTHERLAND Ink Rub Tester Printed Labels & Rub Testing For printed labels, the rub test gauges the amount of abrasion or scuff that may result during shipping, handling or storage. The test may be used for the labels of pharmaceutical products and medical devices, as well as the characters on keypads, for example. These labels must be legible and stand up to wear over time.

Solvent Resistance Rub Test - ASTM D4752 - TRL This test method is used to determine the degree of cure of a baked film by the paint film resistance to a specified solvent. The Solvent Rub Test is usually performed using methyl ethyl ketone (MEK) as the solvent. The MEK resistance or degree of cure applies to paint topcoats and primers. ASTM D4752 involves rubbing the surface of a baked ...

Post a Comment for "39 rub test for labels"